Machine embroidery Basics

In this article we will try to give basic information about machine embroidery, its types, what you need for machine embroidery and where to start if you decide to do it

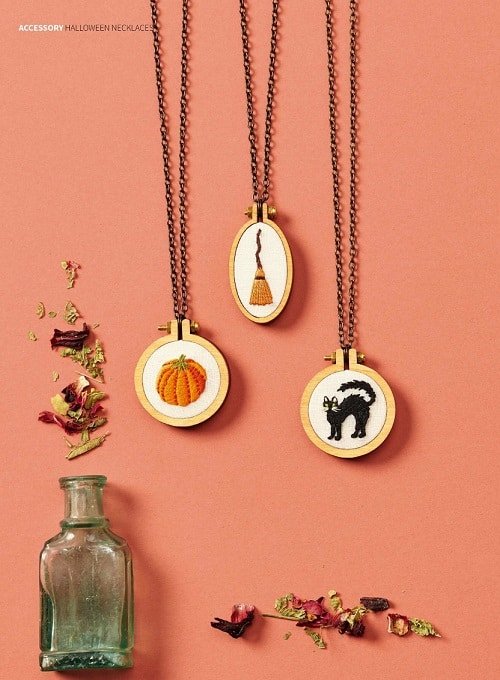

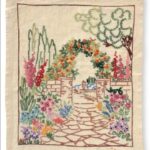

People use embroidery machines to beautify just about anything made of fabric, with children’s clothing being the most popular, followed by household linens, aprons, bed sheets, pillowcases, caps, t-shirts, and sportswear. I’m thinking about launching an embroidery business where I can embroider work clothes, hotel and catering goods, and sportswear for local businesses. Oh, see, I’m at it again – I’m already erecting castles in the sky.

Anyway, I’ve been reading and chatting a lot about embroidery machines and how they function, and I’ve gleaned several pearls of wisdom from folks who work with machine embroidery on a regular basis.

Free style Machine Embroidery

Free motion machine embroidery and machine embroidery done with specific sewing machines are the two types of machine embroidery.

You will do the embroidered work with your standard sewing machine using straight or zig-zag stitches in free-style machine embroidery (free motion embroidery). The feed dogs are lowered, and the standard presser feet are removed, to prevent the cloth from going forward as it does in typical stitching. While the freestyle stitching is being done, the fabric is kept on a hoop and we will be controlling the mobility of the fabric. A sewing machine with a drop-feed control or a plate that covers the feed dogs is required for this project.

You can learn more about this work in this post on Free style Machine Embroidery

Machine Embroidery with specific Embroidery machine

There are such countless various sorts of specific sewing machines for weaving today. Other than the weaving machine, the main things essential for fruitful machine weaving are reasonable needle, right string strain, suitable bobbin and top string, a decent stabilizer as sponsorship for the texture, band to keep the texture level

Fundamentals of Machine Embroidery

It’s a big article I know, but bear with me! By the end you’ll know everything you need to know about the machine embroidery basics !

String utilized for machine weaving

Needle

Pressure

Stabilizer

Weaving plans

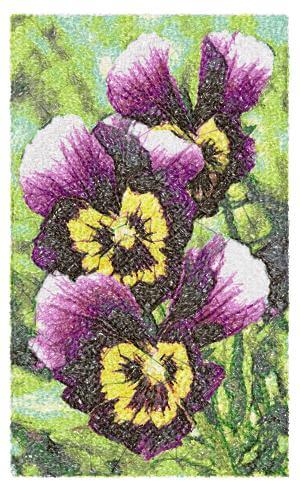

Assuming you have a mechanized weaving machine you can pick any of the stock plans (these are digitized weaving plans that are economically accessible) or get a plan altered from a fine art you have made or photo you have taken. There are particular shops which do this. Look for ‘Weaving Digitizing firms’. They will do the digitizing and convert the plan into the organization your machine will take and in the plan size (stature and width) you need.

As a fledgling complex plans are out of my extension. Straightforward plans are incredible for an amateur.

Assuming you have a photo you can transform it into a line drawing appropriate for machine weaving. Check a photograph and print it full-page in dark scale. Utilizing following paper, define the huge boundaries that characterize the region for each tone. Go over your pencil marks with a dark marker. Check this clearly. Or on the other hand even basically utilize an internet based program like befunky.com. Look at these connected posts: Inspirations for weaving plans ; how to change photograph over to weaving

After you have picked the plan the following thing is to settle on the place of the plan on the piece of clothing/texture, to give it a few unique 3D impacts and so on

String utilized for machine weaving

Basically this is tied in with choosing the top string relies upon your sewing machine and the texture you are weaving on. You really want a string which will confront high velocity sewing without breaking or fraying, be colorfast and endure numerous washings without harm to shading or fastens and give great texture inclusion.

There are three decisions for top string – Rayon weaving string; Polyester string ; Cotton string. Rayon string is an unequaled top pick of most machine weaving lovers as it has an excellent sheen and doesn’t break or shred. You will get an assortment of strong, variegated, and wind tones (with two tones laced together to make a concealing impact). A polyester string is additionally similarly engaging particularly on the grounds that it is less expensive than rayon string. Cotton string is likewise of good execution, however the sheen is more muffled.

Being familiar with string weight is likewise significant. On the off chance that you have a plan which should be sewed thickly, utilize a more slender string any other way it will be excessively massive. The higher the number on the string lighter the heaviness of the string. The bobbin string utilized for sewing machine weaving is ideally of lighter load than the top string.

Needle

You can utilize weaving needles indicated for weaving or ball point needles for weaving on sew textures. You ought to pick the needle contingent upon your texture and thread.Light textures like Silk, flimsy weaves you should utilize a needle with a lower number (#9); Thick textures like denim will require a thicker needle (#16). Any remaining textures can involve needles in the middle. As per what I read, you should be changing your needle after at regular intervals of sewing. Assuming you are utilizing metallic string you should get an extraordinary metallic string needle.

Strain

Keeping up with the legitimate strain while weaving with your sewing machine means to fasten plans to such an extent that the bobbin string doesn’t appear through the essence of the weaving. If so you have a great deal of acclimations to do. Consult your sewing machine manual for additional subtleties on this. Other than the needle and string the main components in machine weaving are stabilizers and circles. You need to get the texture tight on the band. The stabilizer is expected to add strength and dependability to the texture.

Stabilizer (machine embroidery basics)

You want to utilize a support under your weaving so the texture does not list or get harmed. What stabilizers are utilized as support for machine weaving? This relies upon the weight and straightforwardness of the texture and assuming the plan should be exceptionally thick in lines or not.

As currently said a stabilizer is an absolute necessity when you in all actuality do machine weaving. In the event that you have nothing else you can even utilize customary duplicate paper as a stabilizer or spread paper, however use it, you should. The support can be hooped with the texture or it very well may be kept between the machine throat plate and the hooped article of clothing.

The generally utilized stabilizers are removed and tear away. A cutaway stabilizer is utilized for texture with even the littlest of stretch. For all others, a tear-away stabilizer can be utilized just as a cutaway. After the work is done the additional stabilizer is scaled away from the rear of the plan. Now and then they are left all things considered, as assuming that you have an allover plan, wherein case removing doesn’t work.

For sheer transparent textures you should utilize a dissolving stabilizer or tear away stabilizer in light of the fact that the stabilizer will appear through the straightforward texture and it must be removed totally outside the plan from the back. For a plan with a weighty fasten count, you really want a thick stabilizer. You can shrivel the stabilizer utilized with a steam iron – assuming that you figure your stabilizer will contract later and cause puckering and you have preshrunk the texture as of now

Hooping (machine embroidery basics)

Utilize a band that is the nearest size of your plan. Most embroiderers circle the texture and stabilizer together. The hooping is done so that the texture is rigid and level yet without extending the texture of its grain.

Try not to extend the grain of the texture as you circle – this is vital. The hooping for machine weaving is not quite the same as how we loop for the hand weaving. Splash the highest point of the stabilizer with glue shower (brief) and stick them to some unacceptable side of the texture to be weaved. Band the two layers as one unit. Keep the texture and stabilizer on the external band and addition the inward loop on this and fix the screw with the goal that it is tight. Try not to push the inward band excessively. Take the hooped texture to the machine and start your work.

Some of the time circles can make super durable imprints on a few fragile textures – however hooping can represent the moment of truth a machine weaving work so what to do?

What the experts do is to firmly loop the stabilizer first and afterward stick the texture on top. This is finished by applying texture glue on the stabilizer and keeping the texture on top – this way the texture will drift on the loop without getting harmed by hooping.

Fabric for machine embroidery

The impact of a weaving configuration will at last rely a great deal upon the texture on which the weaving is finished. The absolute most generally weaved textures like shirt sews, wedding textures like organza, fabric, crepe, metallic textures are largely very testing. Some are tricky, some transparent, some loosen up of shape. However, there are a few simple traffic circles to this multitude of issues – should be, on the grounds that individuals are continuously weaving something or the other on these.

These days the buzz is supportive of weaving on Nylon lattice and afterward utilizing this on anything article of clothing or frill you need – simply applique it, any place you need it. The upside of this strategy is that you don’t need to unpick the innumerable join in the event you would rather avoid the underlying arrangement. No feeling of dread toward puckering also.

Stay tuned and you’ll learn more about the machine embroidery basics and find lots of free embroidery designes!